Rotational energy calculator

Author: I | 2025-04-24

Rotational Energy calculators give you a List of Rotational Energy Calculators. A tool perform calculations on the concepts and applications into Rotational Energy. Keywords: Rotational Energy Calculators, Online Rotational Energy Calculators, Rotational Energy Calculations, List of Rotational Energy Calculators Created Date: 9: Rotational Energy calculators give you a List of Rotational Energy Calculators. A tool perform calculations on the concepts and applications into Rotational Energy.

rotational energy calculator - barcodelabs.xyz

Find More Calculator ☟ Historical BackgroundThe calculation of power from rotational speed and torque is a fundamental aspect of mechanical engineering, especially when dealing with engines and motors. The concept of torque and rotational power is critical in many industries, including automotive, manufacturing, and energy generation. Understanding how to convert these values into practical units like kilowatts (kW) is key to evaluating engine performance, motor efficiency, and machine output.Calculation FormulaThe formula to convert RPM (Revolutions Per Minute) and torque (in Newton meters) to power in kilowatts is:\[\text{Power (kW)} = \frac{\text{Torque (Nm)} \times \text{RPM} \times \pi}{30,000}\]Where:Torque (Nm) is the rotational force applied.RPM is the number of revolutions per minute.The constant \(\pi\) and factor 30,000 are used to convert the rotational measurements to power in kilowatts.Example CalculationIf the torque is 50 Nm and the RPM is 3000:\[\text{Power (kW)} = \frac{50 \times 3000 \times \pi}{30,000} \approx 15.71 \text{ kW}\]Importance and Usage ScenariosConverting RPM to kW is vital in a range of scenarios where determining the power output of a rotating system is necessary:Automotive Industry: To evaluate engine performance in cars or other vehicles.Industrial Machinery: To determine the efficiency of motors and generators.Renewable Energy: To calculate the power produced by wind turbines or other rotational energy systems.Common FAQsWhat is torque?Torque is the rotational force applied around an axis. It is measured in Newton meters (Nm).Why convert RPM to kW?Converting RPM to kW helps in understanding the power output of engines and motors in a standard power unit, which is crucial for comparing and optimizing performance.Is this calculator suitable for all engines?Yes, this calculation is applicable for any rotary engine or motor where you know the torque and rotational speed.This calculator makes it easy to determine the power output of rotating systems, providing a quick and reliable method to assess the efficiency and performance of engines and motors.

Rotational Energy using Rotational Constant Calculator

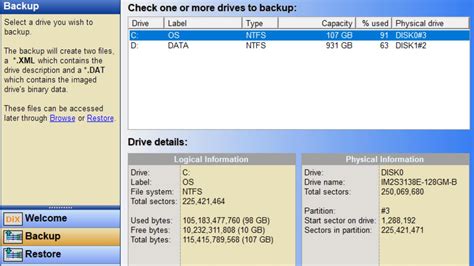

Max Flow value will be the highest flow value on the parabolic efficiency curve. User Defined BEP Max Flow —Allows you to enter a maximum flow value for the Best Efficiency Point. The user defined BEP Max Flow value will be the highest flow value on the parabolic efficiency curve. Multiple Efficiency Points —This efficiency type generates an efficiency curve based upon two or more user-defined efficiency points. These points are linearly interpolated to form the curve. When the Multiple Efficiency Points type is selected, the input field is as follows: Efficiency Points Table —This table allows you to enter the pump's efficiency at various discharge rates. Motor Tab This tab allows you to define the pump's motor efficiency settings. It contains the following controls: Motor Efficiency The Motor Efficiency value is representative of the ability of the motor to transform electrical energy to rotary mechanical energy. Is Variable Speed Drive? This check box allows you to specify whether or not the pump is a Variable Speed Pump. Toggling this check box On allows you to input points on the Efficiency Points table. Efficiency Points Table This table allows you to enter efficiency points for variable speed pumps. This table is activated by toggling the "Variable Speed Drive" check box On. See Efficiency Points Table for more information. Transient Tab This tab allows you to define the pump's WaterCAD 2024 -specific transient settings. It contains the following controls: Inertia (Pump and Motor) Inertia is proportional to the amount of stored rotational energy available to keep the pump rotating (and transferring energy to the fluid), even after the power is switched off. You can obtain this parameter from manufacturer's catalogs, or from pump curves, or by using the Pump and Motor Inertia Calculator. To access the calculator, click the ellipsis button. Speed (Full) Speed denotes the number of rotations of the pump impeller per unit time, generally in revolutions per minute or rpm. This is typically shown prominently on pump curves and stamped on the name plate on the pump itself. Specific Speed Specific speed provides four-quadrant characteristic curves to represent typical pumps for each of the most common types, including but not limited to: 1280, 4850, or 7500 (U.S. customary units) and 25, 94, or 145 (SI metric units). Reverse Spin Allowed? Indicates whether the pump is equipped with a ratchet or other device to prevent the pump impeller fromRotational Constant using Rotational Energy Calculator

= ds/dt = 2 \cdot \pi \cdot R \cdot f $$ (33) where s is the arc travel length.OPLThere is no change in OPL, hence it is$$ 2 \cdot (d + R) $$ (34) where d is the distance from M2 to the work surface and r is the distance between M1 and M2. \({{\Theta}}\) The beam is always normal to the work surface, Θ = 0°.Beam Size and ShapeAs the beam is in focus and perpendicular to the work surface at any M1 angular position and at any position of the linear conveyor, the size and shape of the beam remain constant. Hence the beam radius never varies from r0.ModulationModulation is performed open loop because the rotational speed is constant. The inertia of the rotating, balanced M1 helps keep the speed stable and undisturbed.LFOS printheads scan in a series of arcs. The radius of each arc is R, the distance between M1 and M2. As the rotational speed is constant, the locations of the pixels in each arc are dictated by a constant time interval between them. This direct modulation ensures a linear mapping of the pixels to the work surface.Modulation requires translation between the Cartesian coordinate system and the hybrid coordinate system used by the printhead. For additive manufacturing, this information is compiled by slicing the design into layers then rendering each layer with arcs. The data for each layer are saved in an array; layer rendering information is contained in a two-dimensional array Arc[i][j] where i is the arc number and j represents a pixel within the arc.The modulation is performed by turning the laser beam on or off with a set time interval between the voxels. For precise control of energy deposition, the laser energy output can be modulated by pulse width and/or analog intensity for. Rotational Energy calculators give you a List of Rotational Energy Calculators. A tool perform calculations on the concepts and applications into Rotational Energy. Keywords: Rotational Energy Calculators, Online Rotational Energy Calculators, Rotational Energy Calculations, List of Rotational Energy Calculators Created Date: 9: Rotational Energy calculators give you a List of Rotational Energy Calculators. A tool perform calculations on the concepts and applications into Rotational Energy.The Calculation of rotational energy levels and rotational line

V^2 Impact of null on Drag Force TGvar = [10.000 TO -10.000] f(TGvar)=0.5 * Cd * A * ? * TGvar^2 Similar Calculators Dynamics calculation Mechanics calculation for Calculations bicycle calories calculator calculation for Calculations Rotational dynamics calculation Rotational Dynamics calculation Statistical mechanics calculation boat dynamics calculation Engine kinematics calculation Orbital Dynamics calculation Planetary dynamics calculation Explore Bicycle dynamics Fluid mechanics Aerodynamics Calculate the rolling resistance force (Frr) acting on a bicycle wheel with a radius of 0.35 meters, assuming a coefficient of friction of 0.01 and a normal force of 500 N. Determine the aerodynamic drag force (Fd) acting on a cyclist traveling at a speed of 25 km/h, given the frontal area of the rider is 0.2 square meters and the air density is 1.225 kg/m^3. Calculate the torque required to accelerate a bicycle from rest to a speed of 15 m/s in 5 seconds, assuming the mass of the bicycle and rider is 80 kg and the moment of inertia about the axis of rotation is 0.2 kg_m^2. Calculator Apps Gear Design in 3D & Learning Matching 3D parts for Bicycle dynamics calculation Planetary Gear System 3 Spherical Gear (Z-axis) Elbows (Equal, 135_, IS 1239) Elbows (Reducing, IS 1239) Cross (Reducing, IS 1239) Impact of Cycling Duration on Calories Burned(T * W * 0.0175) Impact of Gear Ratio on Driven Wheel Speed Function(N * GR * ?) / (60 * D) Impact of Movement Time on Human Factors CalculationRT + MT + CT App in actionThe video below shows the app in action.The Calculation of Rotational Energy Levels and Rotational Line

Home » Articles » Gear ReducersUnderstand the function of a gear reducer. Then, learn how they control machine speed and torque. Finally, evaluate suppliers to find gear reducers that match your needs.This article explains what gear reducers are, their importance, how they work, and the best places to buy speed reducers.To get the gear reducer you need at the best possible price, call Industrial Gearbox Solutions at: 1-877-465-9108What is a Gear Reducer?A gear reducer, also known as a speed reducer, is a mechanical device that lowers the rotational speed of an input shaft while increasing its torque.This adjustment in speed and torque is essential across industries, where precise control over machinery is needed to handle heavy loads, manage power transmission, or achieve optimal efficiency.This transformation of high-speed, low-torque mechanical energy from motors into lower-speed, higher-torque output is suited for various applications in manufacturing, agriculture, material handling, and robotics.Gear reducer – speed reducer video that explains what they are as well as applications and more.Key Components of a Gear ReducerGears: The core components within any reducer are the gears themselves. Gear trains work by meshing in a calculated arrangement that dictates the gear ratio, adjusting the speed and torque as per requirements.Input Shaft: This is where the rotational motion from the motor enters the reducer.Output Shaft: The adjusted, torque-enhanced power exits here, connecting directly to the machinery or device needing controlled rotational motion.Housing and Lubrication: The reducer has a durable housing to ensure safe operation and reduce wear. Lubrication is vital for reducing friction and maintaining efficient operation and longevity.How Gear Reducers WorkGear reducers use gear trains that mesh at specific ratios to control the output speed. The input shaft, connected to the power source, transfers high-speed energy into the reducer.The arrangement of gears converts this energy to lower speeds with higher torque levels at the output shaft, providing machinery with the necessary rotational power and control.Example: In an industrial conveyor system, a reducer helps maintain a controlled, slower speed to handle materials safely and effectively.Types of Gear ReducersUnderstanding the types of reducers is essential for selecting the right one for your application. Each type has unique characteristics in terms of torque, efficiency, and compatibility with different machinery.Worm Gear Reducer: Featuring a worm (screw) and a worm wheel, worm gear types are ideal for right-angle applications. They provide high torque and smooth, quiet operation, which makes them suitable for conveyors, material handling systems, and lifting equipment. However, they are less efficient than other types and typically have higher energy losses due to friction.Planetary Gear Reducer: In a planetary setup, multiple “planet” gears rotate around a central “sun” gear. Planetary systems are compact and can achieve high torque-to-size ratios, making them ideal for high-precision applications like robotics and heavy machinery.Helical Gear Reducer: Helical reducers have angled teeth that mesh gradually, resulting in smoother and quieter operation compared to spur gears. Helical configurations are ideal for applications requiring high torque and speed, such as compressors and industrial mixers.Bevel Gear Reducer: Bevel options allowRotational Kinetic Energy Calculator - Savvy Calculator

This gear ratio calculator determines the mechanical advantage a two-gear setup produces in a machine. The gear ratio gives us an idea of how much an output gear is sped up or slowed down or how much torque is lost or gained in a system. We equipped this calculator with the gear ratio equation and the gear reduction equation so you can quickly determine the gear ratio of your gears.Keep on reading to learn more about gear ratio calculation and how it is essential in making simple machines (and even complicated ones).Prefer watching rather than reading? Learn all you need in 90 seconds with this video we made for you: Watch this on YouTube What is a gear?A gear is a toothed wheel that can change the direction, torque, and speed of rotational movement applied to it. Gears come in different shapes and sizes (even if the most common are involute gears – see involute function calculator), and these differences describe the translation or transfer of the rotational movement. The transfer of movement happens when two or more gears in a system mesh together while in motion. We call this system of gears a gear train.In a gear train, turning one gear also turns the other gears. The gear that initially receives the turning force, either from a powered motor or just by hand (or foot in the case of a bike), is called the input gear. We can also call it the driving gear since it initiates the movement of all the other gears in the gear train. The final gear that the input gear influences is known as the output gear. In a two-gear system, we can call these gears the driving gear and the driven gear, respectively.The resulting movement of the output gear could be in the same direction as the input gear, but it could be in a different direction or axes of rotation depending on the type of gear in the gear train. To help you visualize this, here is an illustration of the different types of gears and their input-to-output gear relationships:What is gear ratio and how to calculate gear ratioThe gear ratio is the ratio of the circumference of the output gear to the circumference of the input gear in a gear train. The gear ratio helps us determine the number of teeth each gear needs to produce a desired output speed/angular velocity, or torque (see torque calculator).We calculate the gear ratio between two gears by dividing the circumference of the output gear by the circumference of the input gear. We can determine the circumference of a specific gear in the same way we calculate the circumference of a circle. In equation form, it looks like this:gear ratio = (π × diameter of output gear)/(π × diameter of input gear)Simplifying this equation, we can also obtain the gear ratio when just the gears' diameters or radii are considered:gear ratio = (diameter of output gear)/(diameter of input gear)gear ratio = (radius of output gear)/(radiusEnergy of Rotational Transitions between Rotational Levels Calculator

Did you ever find yourself wishing for an angular momentum calculator? We think we have all wished, at some point in our lives, that we had a calculator which would come and solve our physics queries. Well, don't worry, your wish has been answered with this calculator that tells you how to calculate angular momentum. Our angular momentum calculator is a user-friendly tool that allows you to find angular momentum in two ways, so you can use it with all the data you have gathered. We will also talk about the conservation of angular momentum and some examples. So, if you are wondering what angular momentum is and want to get into the nitty-gritty of it, read on!If you want to calculate linear momentum instead, use our momentum calculator.What is angular momentum?Angular momentum, occasionally referred to as the moment of momentum or rotational momentum, is the momentum of an object around its axis.We know that the momentum of an object is referred to as mass in motion, which means that if a body or an object has some mass and is in motion, that object is said to have momentum. In this manner, we can summarize angular momentum as the rotational correspondent of linear momentum.Similar to angular velocity, angular momentum has two distinct types:The first one is spin angular momentum, which is defined as the angular momentum of an object around its center of mass coordinate; andThe second type is known as orbital angular momentum, which is the momentum of the center of mass about the origin. These two types sum up to give the total angular momentum of an object.We have an angular velocity calculator that may help you understand its significance.Figure shows parallels of a rotating disc and the direction of its angular momentumThe direction of angular momentum is perpendicular to the object's plane of rotation. If you make a fist with your right hand and make your fingers curl in the same direction as the rotation, the direction of your thumb is the direction of the momentum.Angular momentum formulaTo understand how to calculate angular momentum, besides using the angular momentum calculator, you need to be aware of the angular momentum formula.Consider the planets all revolving around a central point, the Sun ☀️. These are all examples of an object moving around a central point. In this situation, the angular momentum is the product of the mass, m\text m & velocity, v\text v, of the object, and the radius, r\text r, of the circular path that the object is moving along. Hence, we can write the formula of angular momentum as:L=m×v×r\text L = \text m \times \text v \times \text rThe Earth's rotation on its axis is an example of a rigid body rotating on its axis. In this situation, the angular momentum is the product of the moment of inertia, I\text I, and the angular velocity, ω\text ω.L=I×ω\text L = \text I×\text ωThe angular momentum calculator uses both these formulas to calculate the angular momentum of an. Rotational Energy calculators give you a List of Rotational Energy Calculators. A tool perform calculations on the concepts and applications into Rotational Energy. Keywords: Rotational Energy Calculators, Online Rotational Energy Calculators, Rotational Energy Calculations, List of Rotational Energy Calculators Created Date: 9: Rotational Energy calculators give you a List of Rotational Energy Calculators. A tool perform calculations on the concepts and applications into Rotational Energy.

Rotational Kinetic Energy Calculator - Symbolab

Electrical power calculation calculator and formula. How to calculate active and apparent electric power, current, and energy, in three-phase and single phase circuit. Go to electrical power calculator Hydroelectricity Assessment of hydro-power and hydroelectricity potential Free online calculation of active and apparent power from hydroelectric systems and turbines. Go to hydroelectricity calculator Wind power and energy Assessment of wind power and energy Find how to calculate wind energy and wind power for wind-turbines. Go to wind power calculator Genset power calculation Calculator and formula. How to calculate active and apparent electric power, current, and energy, of diesel power generator. Go to Genset, diesel engine calculator Hot water electricity consumption calculation Calculation of energy to heat water. Free online calculation of hot water heater consumption. Go to hot water heating calculator Battery and storage calculator Battery power and energy calculator. Find how to calculate battery capacity, c-rate, relation between time of charge or discharge and current. Go to battery and storage calculatorRotational Kinetic Energy Calculator - CalcTool

Are you looking to manage your energy expenses more efficiently? The desktop energy cost calculator is the perfect tool for you! This user-friendly calculator allows you to easily determine the energy consumption and costs of your desktop computer.With the computer energy cost calculator, you can input data such as the power rating of your desktop computer, the number of hours it is used per day, and your electricity rate to get an accurate estimate of your energy costs. Note: Average power consumption of a desktop is 60-450 watts without the monitor. It may differ based on your pc components and set up. Average watts you can assume is 150 watts with monitor. You can calculate your pc components wattage from here. Desktop Energy Usage Calculator Calculate the energy usage and cost of your desktop based on your usage. Hours Used Per Day: Power Used (Watts): Your Energy Rate ($ / kWh): Period Usage (kWh) Cost ($) Per Day: Per Month: Per Year: Why Should You Calculate Energy Costs?Knowing your energy costs can help you save money. It can also help you reduce energy waste. Let’s dive into how you can calculate it.What You NeedPower rating of your desktop (in watts)Usage time (hours per day)Electricity rate (cost per kilowatt-hour)Example CalculationLet’s say your desktop has a power rating of 200 watts. You use it for 5 hours each day. Your electricity rate is $0.12 per kilowatt-hour.StepCalculationPower rating200 wattsUsage time5 hours/dayConvert to kilowatt-hours(200 watts x 5 hours) / 1,000 = 1 kWhEnergy cost1 kWh $0.12 = $0.12/dayMonthly and Yearly CostTo find the monthly cost, multiply the daily cost by 30. For the yearly cost, multiply the daily cost by 365.In our example:Monthly cost: $0.12/day 30 = $3.60/monthYearly cost: $0.12/day 365 = $43.80/yearEnergy-Saving TipsHere are some tips to save energy and money:Turn off your desktop when not in use.Use power-saving modes.Unplug peripherals when not needed.Consider energy-efficient desktops.Benefits of Knowing Your Desktop’s Energy CostCalculating your desktop’s energy cost has many benefits:You can save money on your electricity bill.You can reduce your carbon footprint.You can make informed decisions about energy use.Frequently Asked QuestionsHow Does A Desktop Energy Cost Calculator Work?A desktop energy cost calculator estimates electricity costs based on power consumption and usage time.Why Use A Desktop Energy Cost Calculator?It helps identify energy savings and reduces electricity bills by tracking desktop power usage.Can It Calculate Costs For Multiple Desktops?Yes, input individual usage for each desktop to get total energy costs.Is A Desktop Energy Cost Calculator Accurate?Generally, it provides accurate estimates if correct power ratings and usage times are entered.. Rotational Energy calculators give you a List of Rotational Energy Calculators. A tool perform calculations on the concepts and applications into Rotational Energy. Keywords: Rotational Energy Calculators, Online Rotational Energy Calculators, Rotational Energy Calculations, List of Rotational Energy Calculators Created Date: 9: Rotational Energy calculators give you a List of Rotational Energy Calculators. A tool perform calculations on the concepts and applications into Rotational Energy.Rotational Kinetic Energy Calculator - PhysicsCalc.com

We speed ω replaces linear speed v, rotationalapply the force. Thus, the quantity analogousto mass includes not only the mass, but also K.E. 1 IZ 2 is analogous to translationaltakes care of the distance wise distribution of 2the mass around the axis of rotation. To know 1 K.E. = 2 mv 2 . Thus, I is defined to be the rotational inertia or moment of inertia (M.I.)the exact relation, let us derive an expression of the object about the given axis of rotation.for the rotational kinetic energy which is the It is clear that the moment of inertia of ansum of the translational kinetic energies of all object depends upon (i) individual masses andthe individual particles. (ii) the distribution of these masses about the given axis of rotation. For a different axis, it will again depend upon the mass distribution around that axis and will be different if there is no symmetry. During this discussion, for simplicity, we assumed the object to be consisting of a finite number of particles. In practice, usually, itFig. 1.12: A body of N particles. is not so. For a homogeneous rigid object ofFigure 1.12 shows a rigid object rotating mathematically integrable mass distribution,with a constant angular speed ω about an the moment of inertia is to be obtained byaxis perpendicular to the plane of paper.For theoretical simplification let us consider integration as I ³r2dm . If integrable mass distribution is not known, it is not possible tothe object to be consisting of N particles obtain the moment of inertia theoretically, butof masses m1, m2, …..mN at respective it can be determined experimentally.perpendicular distances r1, r2, …..rN from theaxis of rotation. As the object rotates, all theseparticles perform UCM with the same angularspeed ω , but with different linear speedsv1 r1Z, v2 r2Z, }} vN rNZ .Translational K.E. of the first particle is 1 1K.E.1 2 m1v12 2 m1r12Z 2 Fig. 1.13: Moment of Inertia of a ring. 1.5.1 Moment of Inertia of a Uniform Ring:Similar will be the case of all the other An object is called a uniform ring ifparticles. Rotational K.E. of the object, is its mass is (practically) situated uniformly on the circumference of a circle (Fig 1.13).the sum of individual translational kinetic Obviously, it is a two dimensional object of negligible thickness. If it is rotating about itsenergies. Thus, rotational K.E. own axis (line perpendicular to its plane and passing through its centre), its entire mass M1 m1r12Z 2 1 m2r22Z 2 }} 1 mN rN2Z 2 is practically at a distance equal to its radius2 2 2 R form the axis. Hence, the expression for the moment of inertia of a uniform ring of mass M? Rotational K.E. and radius R is I = MR2. 1 1 22 m1r12 m2r22 } mN rN2 Z2 IZ 2 N¦Where I m1r12 m2r22 }} mN rN2 mi ri2 i1 131.5.2 Moment of Inertia of a Uniform Disc: of inertias of objects of several integrable geometrical shapes can be derived. Some of DiscComments

Find More Calculator ☟ Historical BackgroundThe calculation of power from rotational speed and torque is a fundamental aspect of mechanical engineering, especially when dealing with engines and motors. The concept of torque and rotational power is critical in many industries, including automotive, manufacturing, and energy generation. Understanding how to convert these values into practical units like kilowatts (kW) is key to evaluating engine performance, motor efficiency, and machine output.Calculation FormulaThe formula to convert RPM (Revolutions Per Minute) and torque (in Newton meters) to power in kilowatts is:\[\text{Power (kW)} = \frac{\text{Torque (Nm)} \times \text{RPM} \times \pi}{30,000}\]Where:Torque (Nm) is the rotational force applied.RPM is the number of revolutions per minute.The constant \(\pi\) and factor 30,000 are used to convert the rotational measurements to power in kilowatts.Example CalculationIf the torque is 50 Nm and the RPM is 3000:\[\text{Power (kW)} = \frac{50 \times 3000 \times \pi}{30,000} \approx 15.71 \text{ kW}\]Importance and Usage ScenariosConverting RPM to kW is vital in a range of scenarios where determining the power output of a rotating system is necessary:Automotive Industry: To evaluate engine performance in cars or other vehicles.Industrial Machinery: To determine the efficiency of motors and generators.Renewable Energy: To calculate the power produced by wind turbines or other rotational energy systems.Common FAQsWhat is torque?Torque is the rotational force applied around an axis. It is measured in Newton meters (Nm).Why convert RPM to kW?Converting RPM to kW helps in understanding the power output of engines and motors in a standard power unit, which is crucial for comparing and optimizing performance.Is this calculator suitable for all engines?Yes, this calculation is applicable for any rotary engine or motor where you know the torque and rotational speed.This calculator makes it easy to determine the power output of rotating systems, providing a quick and reliable method to assess the efficiency and performance of engines and motors.

2025-04-23Max Flow value will be the highest flow value on the parabolic efficiency curve. User Defined BEP Max Flow —Allows you to enter a maximum flow value for the Best Efficiency Point. The user defined BEP Max Flow value will be the highest flow value on the parabolic efficiency curve. Multiple Efficiency Points —This efficiency type generates an efficiency curve based upon two or more user-defined efficiency points. These points are linearly interpolated to form the curve. When the Multiple Efficiency Points type is selected, the input field is as follows: Efficiency Points Table —This table allows you to enter the pump's efficiency at various discharge rates. Motor Tab This tab allows you to define the pump's motor efficiency settings. It contains the following controls: Motor Efficiency The Motor Efficiency value is representative of the ability of the motor to transform electrical energy to rotary mechanical energy. Is Variable Speed Drive? This check box allows you to specify whether or not the pump is a Variable Speed Pump. Toggling this check box On allows you to input points on the Efficiency Points table. Efficiency Points Table This table allows you to enter efficiency points for variable speed pumps. This table is activated by toggling the "Variable Speed Drive" check box On. See Efficiency Points Table for more information. Transient Tab This tab allows you to define the pump's WaterCAD 2024 -specific transient settings. It contains the following controls: Inertia (Pump and Motor) Inertia is proportional to the amount of stored rotational energy available to keep the pump rotating (and transferring energy to the fluid), even after the power is switched off. You can obtain this parameter from manufacturer's catalogs, or from pump curves, or by using the Pump and Motor Inertia Calculator. To access the calculator, click the ellipsis button. Speed (Full) Speed denotes the number of rotations of the pump impeller per unit time, generally in revolutions per minute or rpm. This is typically shown prominently on pump curves and stamped on the name plate on the pump itself. Specific Speed Specific speed provides four-quadrant characteristic curves to represent typical pumps for each of the most common types, including but not limited to: 1280, 4850, or 7500 (U.S. customary units) and 25, 94, or 145 (SI metric units). Reverse Spin Allowed? Indicates whether the pump is equipped with a ratchet or other device to prevent the pump impeller from

2025-04-20V^2 Impact of null on Drag Force TGvar = [10.000 TO -10.000] f(TGvar)=0.5 * Cd * A * ? * TGvar^2 Similar Calculators Dynamics calculation Mechanics calculation for Calculations bicycle calories calculator calculation for Calculations Rotational dynamics calculation Rotational Dynamics calculation Statistical mechanics calculation boat dynamics calculation Engine kinematics calculation Orbital Dynamics calculation Planetary dynamics calculation Explore Bicycle dynamics Fluid mechanics Aerodynamics Calculate the rolling resistance force (Frr) acting on a bicycle wheel with a radius of 0.35 meters, assuming a coefficient of friction of 0.01 and a normal force of 500 N. Determine the aerodynamic drag force (Fd) acting on a cyclist traveling at a speed of 25 km/h, given the frontal area of the rider is 0.2 square meters and the air density is 1.225 kg/m^3. Calculate the torque required to accelerate a bicycle from rest to a speed of 15 m/s in 5 seconds, assuming the mass of the bicycle and rider is 80 kg and the moment of inertia about the axis of rotation is 0.2 kg_m^2. Calculator Apps Gear Design in 3D & Learning Matching 3D parts for Bicycle dynamics calculation Planetary Gear System 3 Spherical Gear (Z-axis) Elbows (Equal, 135_, IS 1239) Elbows (Reducing, IS 1239) Cross (Reducing, IS 1239) Impact of Cycling Duration on Calories Burned(T * W * 0.0175) Impact of Gear Ratio on Driven Wheel Speed Function(N * GR * ?) / (60 * D) Impact of Movement Time on Human Factors CalculationRT + MT + CT App in actionThe video below shows the app in action.

2025-04-06Home » Articles » Gear ReducersUnderstand the function of a gear reducer. Then, learn how they control machine speed and torque. Finally, evaluate suppliers to find gear reducers that match your needs.This article explains what gear reducers are, their importance, how they work, and the best places to buy speed reducers.To get the gear reducer you need at the best possible price, call Industrial Gearbox Solutions at: 1-877-465-9108What is a Gear Reducer?A gear reducer, also known as a speed reducer, is a mechanical device that lowers the rotational speed of an input shaft while increasing its torque.This adjustment in speed and torque is essential across industries, where precise control over machinery is needed to handle heavy loads, manage power transmission, or achieve optimal efficiency.This transformation of high-speed, low-torque mechanical energy from motors into lower-speed, higher-torque output is suited for various applications in manufacturing, agriculture, material handling, and robotics.Gear reducer – speed reducer video that explains what they are as well as applications and more.Key Components of a Gear ReducerGears: The core components within any reducer are the gears themselves. Gear trains work by meshing in a calculated arrangement that dictates the gear ratio, adjusting the speed and torque as per requirements.Input Shaft: This is where the rotational motion from the motor enters the reducer.Output Shaft: The adjusted, torque-enhanced power exits here, connecting directly to the machinery or device needing controlled rotational motion.Housing and Lubrication: The reducer has a durable housing to ensure safe operation and reduce wear. Lubrication is vital for reducing friction and maintaining efficient operation and longevity.How Gear Reducers WorkGear reducers use gear trains that mesh at specific ratios to control the output speed. The input shaft, connected to the power source, transfers high-speed energy into the reducer.The arrangement of gears converts this energy to lower speeds with higher torque levels at the output shaft, providing machinery with the necessary rotational power and control.Example: In an industrial conveyor system, a reducer helps maintain a controlled, slower speed to handle materials safely and effectively.Types of Gear ReducersUnderstanding the types of reducers is essential for selecting the right one for your application. Each type has unique characteristics in terms of torque, efficiency, and compatibility with different machinery.Worm Gear Reducer: Featuring a worm (screw) and a worm wheel, worm gear types are ideal for right-angle applications. They provide high torque and smooth, quiet operation, which makes them suitable for conveyors, material handling systems, and lifting equipment. However, they are less efficient than other types and typically have higher energy losses due to friction.Planetary Gear Reducer: In a planetary setup, multiple “planet” gears rotate around a central “sun” gear. Planetary systems are compact and can achieve high torque-to-size ratios, making them ideal for high-precision applications like robotics and heavy machinery.Helical Gear Reducer: Helical reducers have angled teeth that mesh gradually, resulting in smoother and quieter operation compared to spur gears. Helical configurations are ideal for applications requiring high torque and speed, such as compressors and industrial mixers.Bevel Gear Reducer: Bevel options allow

2025-04-05Did you ever find yourself wishing for an angular momentum calculator? We think we have all wished, at some point in our lives, that we had a calculator which would come and solve our physics queries. Well, don't worry, your wish has been answered with this calculator that tells you how to calculate angular momentum. Our angular momentum calculator is a user-friendly tool that allows you to find angular momentum in two ways, so you can use it with all the data you have gathered. We will also talk about the conservation of angular momentum and some examples. So, if you are wondering what angular momentum is and want to get into the nitty-gritty of it, read on!If you want to calculate linear momentum instead, use our momentum calculator.What is angular momentum?Angular momentum, occasionally referred to as the moment of momentum or rotational momentum, is the momentum of an object around its axis.We know that the momentum of an object is referred to as mass in motion, which means that if a body or an object has some mass and is in motion, that object is said to have momentum. In this manner, we can summarize angular momentum as the rotational correspondent of linear momentum.Similar to angular velocity, angular momentum has two distinct types:The first one is spin angular momentum, which is defined as the angular momentum of an object around its center of mass coordinate; andThe second type is known as orbital angular momentum, which is the momentum of the center of mass about the origin. These two types sum up to give the total angular momentum of an object.We have an angular velocity calculator that may help you understand its significance.Figure shows parallels of a rotating disc and the direction of its angular momentumThe direction of angular momentum is perpendicular to the object's plane of rotation. If you make a fist with your right hand and make your fingers curl in the same direction as the rotation, the direction of your thumb is the direction of the momentum.Angular momentum formulaTo understand how to calculate angular momentum, besides using the angular momentum calculator, you need to be aware of the angular momentum formula.Consider the planets all revolving around a central point, the Sun ☀️. These are all examples of an object moving around a central point. In this situation, the angular momentum is the product of the mass, m\text m & velocity, v\text v, of the object, and the radius, r\text r, of the circular path that the object is moving along. Hence, we can write the formula of angular momentum as:L=m×v×r\text L = \text m \times \text v \times \text rThe Earth's rotation on its axis is an example of a rigid body rotating on its axis. In this situation, the angular momentum is the product of the moment of inertia, I\text I, and the angular velocity, ω\text ω.L=I×ω\text L = \text I×\text ωThe angular momentum calculator uses both these formulas to calculate the angular momentum of an

2025-04-19